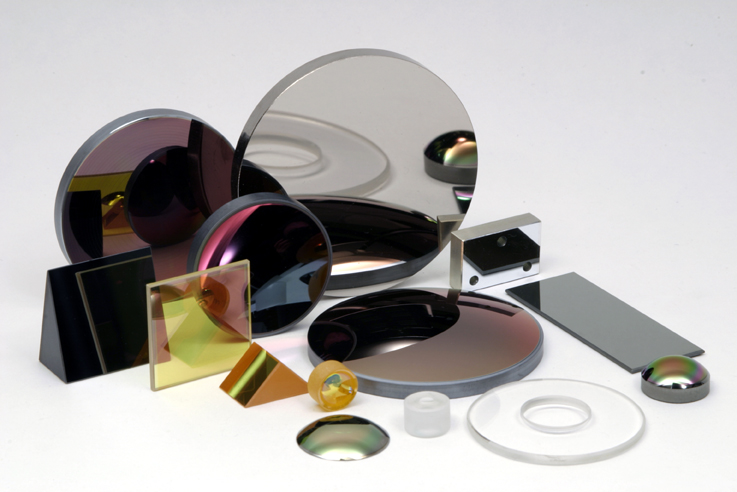

Lens Elements

Janos technology is a leader in single point diamond machining technology. We offer precision refractive and reflective optics manufactured with CNC two-axis single point diamond machining equipment. Janos caters to diverse industries such as aerospace, defense, medical devices, semiconductor manufacturing, and scientific research, where high-quality optical components are essential for various applications.

Surface roughness ranging from 5-100 Å RMS is quite common in precision optics manufacturing using single point diamond machining equipment. The actual surface roughness achieved can vary based on factors such as the material being machined, the specific configuration of the optical component, and the machining parameters used.

Maintaining consistent and controlled surface roughness is crucial for ensuring optical components meet performance specifications and minimize undesirable optical effects such as scattering or aberrations. Therefore, manufacturers typically employ rigorous quality control measures and inspection techniques to verify surface quality throughout the manufacturing process.

Materials

| Germanium | Silicon | Zinc Selenide | Zinc Sulfide |

| Mutli-Spectral ZnS | Calcium Fluoride | Barium Fluoride | Magnesium Fluoride |

| AMTIR | Chalcogenide (All) | GASIR | Gallium Arsenide |

| Aluminum | Copper | Electroless Nickel Plating |

Capabilities

Aspheric Lenses

Spherical Lenses

Plano Lenses

Binary Diffractive Lenses

Free Form – Slow Tool Servo

On-Axis Metal Mirrors

Off-Axis Metal Mirrors

Torroidal Metal Mirrors

Cylindrical Metal Mirrors

In order to provide our customers with precision testing and metrology techniques, manufacturers can ensure that optical components meet the stringent quality standards required for various applications, ranging from aerospace and defense to medical imaging and telecommunications.

Overall, investing in state-of-the-art testing and metrology equipment demonstrates a commitment to quality, innovation, and continuous improvement, positioning manufacturers for long-term success in the competitive optical components market.

Machining & Metrology Capabilities

CNC Generating:

By leveraging state-of-the-art CNC generating equipment, Janos is well-positioned to deliver high-precision optical components that meet the evolving demands of modern technology and industry.

CNC Centering:

Our CNC centering machine expands our capabilities in lens manufacturing, enabling efficient processing of a wide range of lens sizes and shapes with high precision and flexibility.

Machining Tolerances

| Specification | Standard | Typical | Limits |

| Diameter | + 0 / – 0.13mm | + / – 0.05mm | ± 0.005mm |

| Center Thickness | ± 0.10mm | ± 0.05mm | ± 0.005mm |

| Clear Aperture (Minimum) | 80% | 85% | 98% |

| Radius Tolerance | ± 0.10% | ± 0.05% | ± 0.03% |

| Power (Polished Spherical) | 4 fr @ 0.6328µm | 3 fr @ 0.6328µm | 1 fr @ 0.6328µm |

| Irregularity (Polished) |

1 fr @ 0.6328µm | 0.5 fr @ 0.6328µm | 0.2 fr @ 0.6328µm |

| Irregularity(Diamond Turned Lens) | 1 – 3 fr @ 0.6328µm | 1 fr @ 0.6328µm | 0.1 fr @ 0.6328µm |

| Flatness (Polished Plano) |

4 fr @ 0.6328µm | 1 fr @ 0.6328µm | 0.1 fr @ 0.6328µm |

| Irregularity (Polished Plano) |

1 fr @ 0.6328µm | 0.5 fr @ 0.6328µm | 0.1 fr @ 0.6328µm |

| Edge Thickness Variation | ≤ 0.025mm | ≤ 0.012mm | ≤ 0.005mm |

| Parallelism (Windows) | ≤ 3 minutes | ≤1 minute | ≤ 0.5 second |

| Surface Roughness (Material Dependent) | < 65 Å rms | ≤ 50 Å rms | ≤ 5 Å rms |

| Surface Quality (Polished) (Per MIL-PRF-13830 unless otherwise specified) |

60-40 – – |

80-50 60-40 40-20 |

20-10 10-5 – |

*specs subject to change depending on the material being machined*

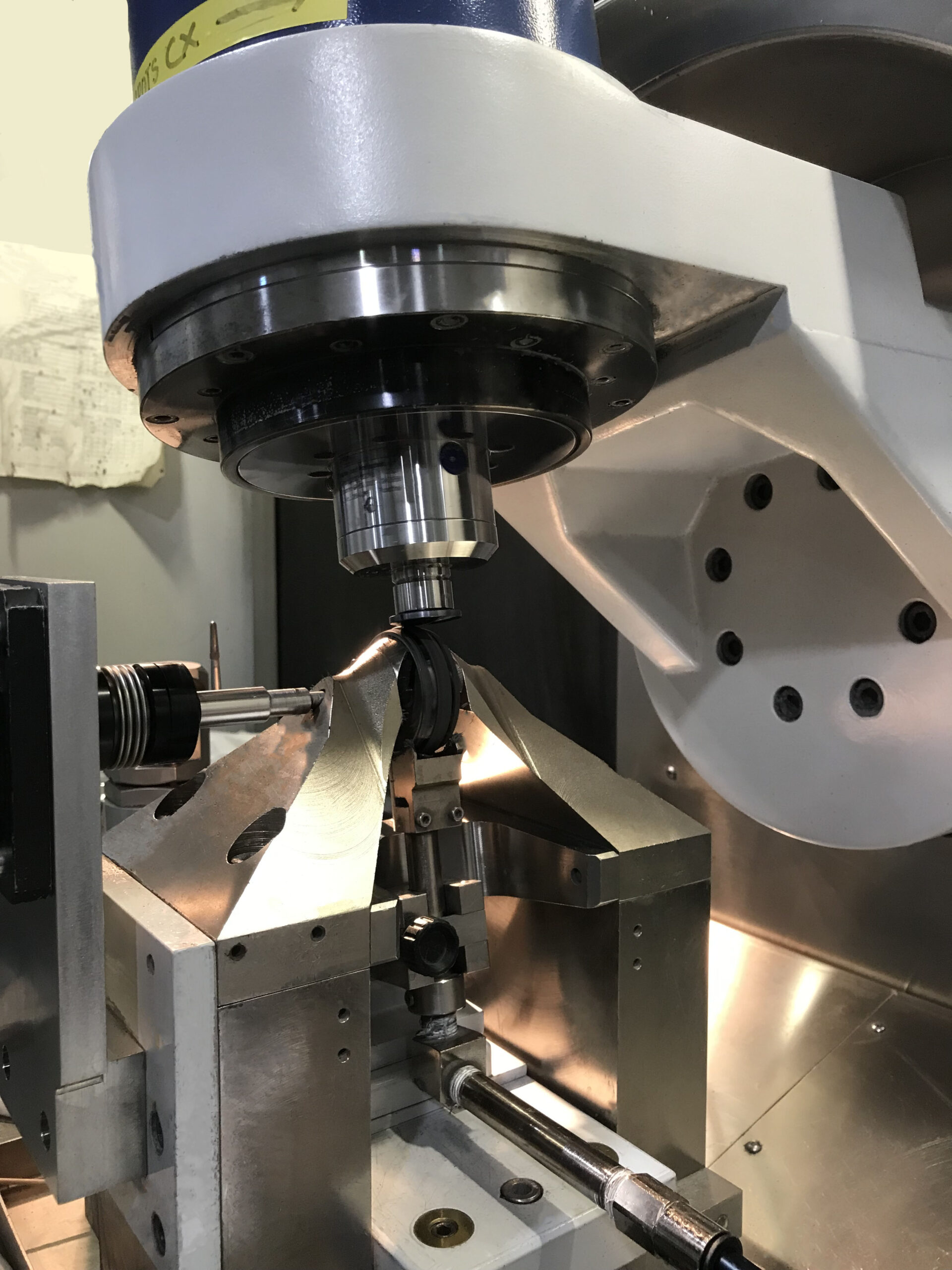

Diamond Turning Equipment:

Discover Janos Technologies’ cutting-edge diamond turning capabilities, where precision meets perfection. Utilizing advanced machinery and expert craftsmanship, we specialize in shaping optical components to unparalleled levels of accuracy and smoothness. From aerospace to telecommunications, trust us to deliver superior results with uncompromising quality and precision that outshines the rest.

7 Diamond Turning Machines

Can turn up to 430mm or 17”.